Heavy industries such as steel, cement, and mining are among the most carbon-intensive sectors globally and account for up to 20% of global CO₂ emissions. Decarbonizing these sectors is critical to achieving net-zero goals and advancing the energy transition. While these industries face significant challenges due to their reliance on high-temperature processes and fossil fuels, the emergence of innovative strategies and technologies is helping to transform operations. Additionally, the mining sector, essential for supplying critical materials like iron ore, is addressing its own decarbonization challenges while enabling the production of low-carbon technologies.

- Strategies for reducing carbon emissions in heavy industries

- Innovations enabling decarbonization in heavy industries

- Decarbonizing mining operations

Strategies for reducing carbon emissions in heavy industries

Decarbonizing heavy industries requires a multi-faceted approach to address the unique challenges of energy-intensive production processes. Key strategies include adopting alternative fuels and feedstocks, energy efficiency and process optimization, sectoral collaboration and regulatory support.

Heavy industries are transitioning from fossil fuels to alternative energy sources such as green hydrogen, biofuels, and electrification. The steel industry is piloting direct reduced iron (DRI) processes using hydrogen instead of coal-based blast furnaces. Major companies like SSAB and ArcelorMittal have launched projects to produce steel with up to 90% fewer emissions using hydrogen-based DRI, with SSAB aiming for commercial production by 2026. Similarly, the cement sector is integrating alternative materials like calcined clay and industrial waste as feedstocks to reduce reliance on traditional clinker, which accounts for the majority of its emissions.

Energy efficiency remains a cornerstone of decarbonization in heavy industries. Advanced technologies such as AI-driven process control, waste heat recovery systems, and high-efficiency kilns are reducing energy consumption across sectors. For example, AI-driven systems used in steel mills can optimize energy use in real time, cutting operational emissions by up to 10%. Cement manufacturers are deploying carbon capture, utilization, and storage (CCUS) technologies to capture emissions directly from production processes, with companies like Heidelberg Materials leading the way in deploying full-scale CCUS systems.

Cross-sector collaboration and supportive policy frameworks are critical for scaling decarbonization efforts. Initiatives such as the Mission Possible Partnership are bringing together industry leaders, governments, and financial institutions to establish roadmaps for decarbonizing heavy industries. Regulatory measures, including carbon pricing and emissions trading systems, are incentivizing industries to adopt low-carbon technologies – for example, the European Union’s Carbon Border Adjustment Mechanism is designed to level the playing field by penalizing high-carbon imports, encouraging global adoption of cleaner processes.

Innovations enabling decarbonization in heavy industries

The path to decarbonizing heavy industries relies heavily on technological innovation and digital transformation. The industrial landscape is now being transformed by breakthrough technologies for emissions reduction, electrification and renewable integration, and digital optimization.

Innovations like green hydrogen and CCUS technologies are reshaping the landscape for heavy industries. Hydrogen, particularly green hydrogen produced via electrolysis using renewable energy, has the potential to replace fossil fuels in high-temperature processes. Projects like the Hydrogen Energy Supply Chain in Australia are scaling hydrogen production to support industrial decarbonization. Additionally, CCUS is advancing rapidly, with global capacity expected to triple by 2030, capturing emissions from cement plants, steel mills, and power stations for storage or conversion into valuable byproducts.

Electrification is another key pathway for decarbonizing heavy industries. Electric arc furnaces, powered by renewable electricity, are replacing traditional blast furnaces in steel production, significantly reducing emissions. In the cement sector, electrification of rotary kilns is being explored to cut reliance on fossil fuels. Grid modernization and on-site renewable energy installations are enabling industries to access clean power, with companies leveraging solar and wind energy to decarbonize production facilities.

Digital technologies, including artificial intelligence, machine learning and sensors, are helping to unlock further efficiencies in industrial operations. Predictive maintenance systems optimize equipment performance, reducing downtime and energy waste. For example, sensors embedded in cement kilns can provide real-time data to ensure operations run at optimal efficiency, thereby reducing energy consumption by up to 20%. AI-driven analytics are also helping companies model and simulate low-carbon process improvements, accelerating the adoption of sustainable practices.

Decarbonizing mining operations

The mining sector is not only essential for enabling the energy transition but also faces increasing pressure to decarbonize its own operations. To meet these demands, mining companies are focusing on electrifying equipment, scaling operations to unprecedented levels, and leveraging the role of iron ore in decarbonizing steel production. Innovation is at the heart of these changes, ensuring that mining becomes a sustainable and efficient backbone for the global energy transition.

Mining companies are rapidly adopting electrification to minimize reliance on diesel-powered machinery and significantly reduce operational emissions. Battery-electric vehicles, such as haul trucks and loaders, are increasingly deployed at mining sites worldwide. Major players like BHP, Rio Tinto and Fortescue are leading the way by working with equipment suppliers to fully electrify their fleets, aiming to lower emissions by up to 50% compared to traditional diesel-powered equipment. Renewable energy sources, including solar and wind, are being integrated into mining operations to power equipment and processing facilities, reducing dependence on fossil fuels and contributing to broader decarbonization goals.

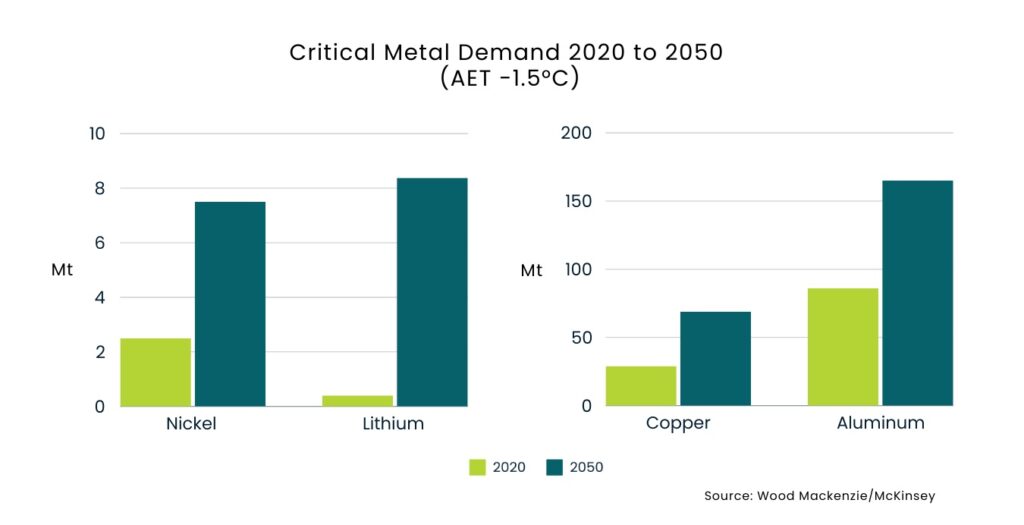

Scaling mining operations is essential to addressing the unprecedented surge in global demand for minerals critical to the energy transition, including iron ore, copper, and lithium. According to the World Bank, the production of key minerals needed for clean energy technologies must increase by nearly 500% by 2050 to meet global climate goals. Demand for lithium alone is projected to grow over 40 times by 2050, while copper demand is expected to double by 2050 due to its essential role in renewable energy systems and electric vehicles. To meet these needs, mining companies are fast-tracking new project developments and expanding existing operations. Advanced technologies like AI-driven exploration are playing a pivotal role, enabling faster and more accurate identification of high-grade deposits, reducing discovery times, and optimizing resource extraction to meet growing demand efficiently.

Iron ore is the most mined mineral on the planet with miners producing over 3 billion tonnes of iron ore each year, representing ~94% of all mined metals, with the primary use (98%) being to make steel. Steel is critical to the energy transition because it has an essential role in renewable energy technologies and is vital for solar panel frames, electric vehicle components, battery casings, and accounts for ~75% of the material used in wind turbines, making iron ore indispensable for scaling wind energy production. The demand for iron and steel is expected to grow significantly in the coming decades due to other factors too. Global population growth, rapid urban development, and economic expansion in emerging economies is further increasing the demand for steel in the construction of new buildings, utilities, and transportation infrastructure such as bridges, airplanes, and ships. The International Energy Agency projects that over 200 million tonnes of high-grade iron ore will be required annually by 2050 to achieve net-zero emissions in steelmaking, emphasizing the urgency of scaling efficient and reliable mining operations. By securing a stable supply of high-quality iron ore, the mining sector is enabling the decarbonization of heavy industries and supporting the broader energy transition.

Mining is not only foundational to the energy transition but is also evolving to meet the demands of a decarbonized future. By embracing innovation and scaling responsibly, the industry is poised to remain a critical enabler of global progress toward net-zero emissions.

- Explore the next article in our Energy Transition series: The Circular Economy in the Energy Transition

I-ROX is open to industry input, collaboration and support – both financially and technically. If you are interested in discussing pulsed-power technology or any other element of collaboration, please contact us for more information.