Electrification is essential in the global shift toward cleaner, more sustainable energy systems, directly contributing to decarbonization across multiple sectors such as transportation, buildings, and manufacturing. Transitioning from fossil fuels to electric-powered systems, such as electric vehicles (EVs), heat pumps and industrial electric machinery has the potential to significantly reduce greenhouse gas (GHG) emissions. However, achieving large-scale electrification requires robust grid infrastructure, supportive policies, and investment in renewable energy to meet rising electricity demand sustainably. This aligns with the growing emphasis on sustainable mining practices that are aiming to minimize the environmental impact of mineral extraction while securing the resources needed for a low-carbon future. With continued advancements in renewable technology, sustainable supply chains, and supportive regulatory frameworks, electrification stands as a cornerstone in achieving global net-zero climate targets.

- The shift to electric vehicles in decarbonizing energy systems

- Electric heating systems as a decarbonization tool

- Industrial electrification for sustainable manufacturing

- Mining’s role and challenges in electrification

The shift to electric vehicles in decarbonizing energy systems

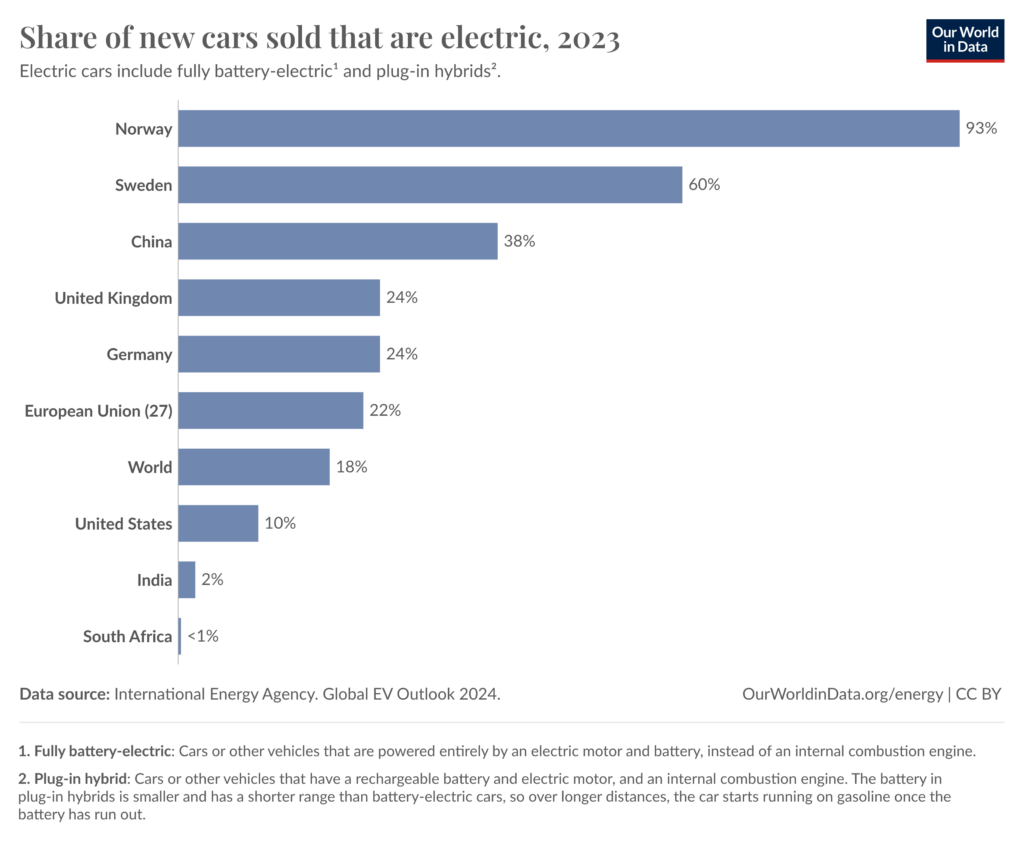

Electric vehicles (EVs) are a major component of the electrification landscape, helping to reduce emissions in one of the largest polluting sectors – transportation. Replacing internal combustion engine (ICE) vehicles with EVs can significantly lower carbon emissions, especially when the electricity used for charging comes from renewable sources. Studies indicate that EVs produce about half the emissions of their ICE counterparts over their lifetime, considering both manufacturing and operational phases. Governments and automakers worldwide have set ambitious targets for EV adoption, for example, the US and the EU are aiming for EVs to make up over 50% of new car sales by 2030, a shift that could reduce transportation emissions by as much as 60% by 2050.

Continued innovation and advances in battery technology are making EV adoption more feasible and attractive. Today’s EV batteries have improved in energy density, durability, and charging speed, allowing for longer ranges and faster recharging times. Innovations in solid-state batteries, expected to hit the market in the next few years, promise to further enhance battery performance while reducing costs. Expanding EV charging infrastructure and investments in ultra-fast chargers, especially in rural and high-demand urban areas, are making charging more convenient and accessible. This infrastructure and other incentives, such as tax credits and rebates, are accelerating the global shift toward EVs.

Electric heating systems as a decarbonization tool

Electric heating in residential, commercial, and industrial spaces is another key area where electrification can significantly reduce carbon emissions. In many regions, electric heat pumps are replacing traditional gas and oil heating systems, which are less efficient and emit more GHG. Heat pumps are three to five times more efficient than conventional heating systems, as they transfer heat rather than generate it. In Europe, where heating accounts for roughly 40% of energy use, transitioning to electric heating could reduce emissions substantially, especially as grids are increasingly powered by renewable energy.

One advantage of electric heating systems is that they can be integrated into a growing renewable grid, allowing homes and businesses to be powered by green electricity. As heat pumps are developed to handle even lower temperatures, they are becoming a viable option in colder regions, reducing dependency on gas heating. To further encourage the adoption of electric heating, subsidies and incentives are being provided in many regions, alongside regulations that limit the installation of new gas-based heating systems in favor of cleaner alternatives.

Industrial electrification for sustainable manufacturing

Industrial processes are typically energy-intensive and rely heavily on fossil fuels to generate heat and power. The shift to industrial electrification promises significant emission reductions, as electricity-based systems offer cleaner and increasingly more efficient solutions to generate high temperatures and power heavy equipment. Advanced electric boilers, furnaces, and motors are being developed to electrify industrial operations, and electric systems are proving to be more energy-efficient and cost-effective than traditional alternatives.

However, electrifying the industrial sector requires infrastructure upgrades and reliable, low-cost electricity sources. Industries involved in manufacturing, mining, and processing are making progress by integrating electric options for high-temperature heat, which traditionally requires large amounts of fossil fuel, while electric heat pumps are increasingly being used in mid-temperature processes, reducing fuel costs and emissions. As electrification becomes more prevalent in these sectors, supporting policies and renewable energy capacity expansions will be crucial for maintaining cost efficiency and energy stability. McKinsey estimates that 50% of the energy needed for industrial processes could be replaced by electricity. The growth of renewable energy and price decreases in electricity generation could make this shift economically attractive, unlocking large-scale emission reductions.

Mining’s role and challenges in electrification

The electrification of the mining sector is essential for sourcing the critical minerals that drive renewable technologies and for reducing the sector’s emissions, and sets the stage for a sustainable, resilient supply chain that can meet the demands of an electrified world. As the demand for EVs, electric heating, and industrial electrification rises, so does the need for copper, lithium, nickel, and other critical minerals that are essential for manufacturing batteries, electric motors, and other components central to the electrification effort. The mining industry faces the dual challenge of expanding production to meet this demand while significantly reducing its own carbon footprint.

Traditional mining relies heavily on diesel-powered machinery, which contributes significantly to the industry’s carbon footprint. Electrifying some mining equipment has already proven very effective in reducing emissions. However, the further electrification of mining processes could double electricity demand in mining, requiring careful management of power supply and infrastructure. To mitigate this increase in demand, some mines are going full-circle by installing local solar or wind farms to supply their own energy source and cut supply costs. It is clear that innovation in mining extraction and operations will be key to shaping the next chapter in mining.

Electrification is a critical strategy in the global energy transition, offering pathways to reduce emissions across transportation, heating, and industrial sectors. With sustainable practices in critical mineral sourcing and infrastructure investment, electrification can help drive progress toward a net-zero future.

- Explore the next article in our Energy Transition series: Energy Storage – Powering the Energy Transition

I-ROX is open to industry input, collaboration and support – both financially and technically. If you are interested in discussing pulsed-power technology, or any other element of collaboration, please contact us for more information.